Handmade

Handmade Goods Industry Of Pakistan

FIFA World Cup 2018 is just a day away now. The excitement among football fans is at its peak. Everybody is posting their pictures wearing their favourite team’s shirt. Debates have already started on social media about which player will give the best performance and which player will fail to fulfil the fans’ expectations. Now everyone is waiting for 14th June when the event will begin in Russia.

My blog is not sports blog but as I support handmade and handicrafts, so why not to spotlight this proud moment of Pakistan? I am going to share today handmade footballs making in Pakistan. I am sure you will find this article interesting.

The Adidas Telstar 18 and The Handmade Goods Industry Of Pakistan

For Pakistani football fans, the happiness is double. The most significant event in the world of football is here, and footballs made in Pakistan will be used in the tournament. The latter is something every Pakistani is proud of, even the ones who are not fans of football. There is enough negativity in the world today, and we rarely see good news about Pakistan in the international media. The Adidas Telstar 18, the official match ball of FIFA World Cup 2018, has changed that. Forward Sports, a sports equipment manufacturing company from Sialkot, Pakistan, produces 700,000 balls per month for renowned brands worldwide. Footballs made by Forward Sports have been used in many International events including UEFA Champions League. Forward Sports also produced Adidas Brazuca, the official match ball for the FIFA World Cup 2014.

Today I am going to share some info about the making of these footballs in Sialkot, Pakistan. I hope you will enjoy this article and step by step images. Special thanks to the wonderful photographer behind all of these clicks, Amjad bhai from Unmaderhyme. He allowed me to share these photography images on Creative Khadija blog.

The Making of A Football:

The hard work of many workers goes into the making of each football. To ensure that the shapes of all panels remain the same, they are die cut using a very accurate tool. A sheet of material is used to cut the panels, and then holes are punched into each panel for stitching.

Then comes the coloring process. A complex coloring and designing procedure supervised by the experts ensure that the football forms a pattern when all panels are colored.

All the panels are then hand stitched by workers. Even an experienced worker will require up to three hours to stitch a football. The last seam alone will take 15 minutes of a worker’s time. Male and female workers working in the sports’ equipment manufacturing companies in Sialkot spend hours on stitching a football, and the perfect final product speaks volume of their talent.

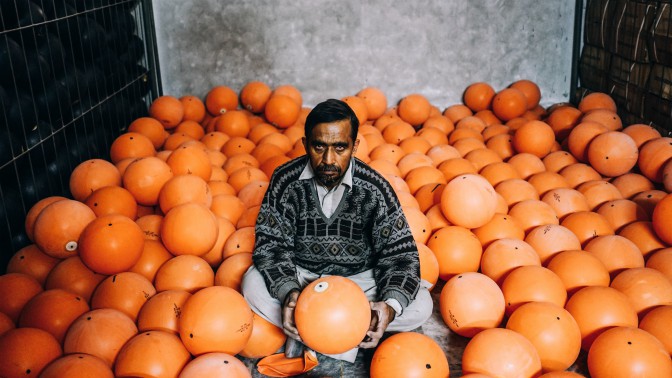

Getting the tubes ready for inserting in the footballs!

The final product is a masterpiece. Isn’t it?

In the modern types of footballs, however, the panels are not stitched but glued together. The Adidas Telstar 18 is also a thermally bonded football.

The Beauty of Pakistani Hand Made Products:

Pakistan’s handmade products are known all over the world. Whether it’s the artistic clothes and shawls that represent the culture of Pakistan or the handmade furniture that is loved all over the world, the traditional to-die-for handmade shoes or the sports equipment that end up in big sports events, the hard work and creativity of Pakistani people is reflected in the quality of each handmade good. The industry of handmade goods needs constant support from the people and the government to ensure it continues to produce world-class products and highlight the positive image of Pakistan in the world.

You can also check my post from archives about Pakistani Footballs in FIFA Worldcup.

Thanks